For in-line colouring of extruded and co-extruded type snacks, pet snacks or breakfast cereal

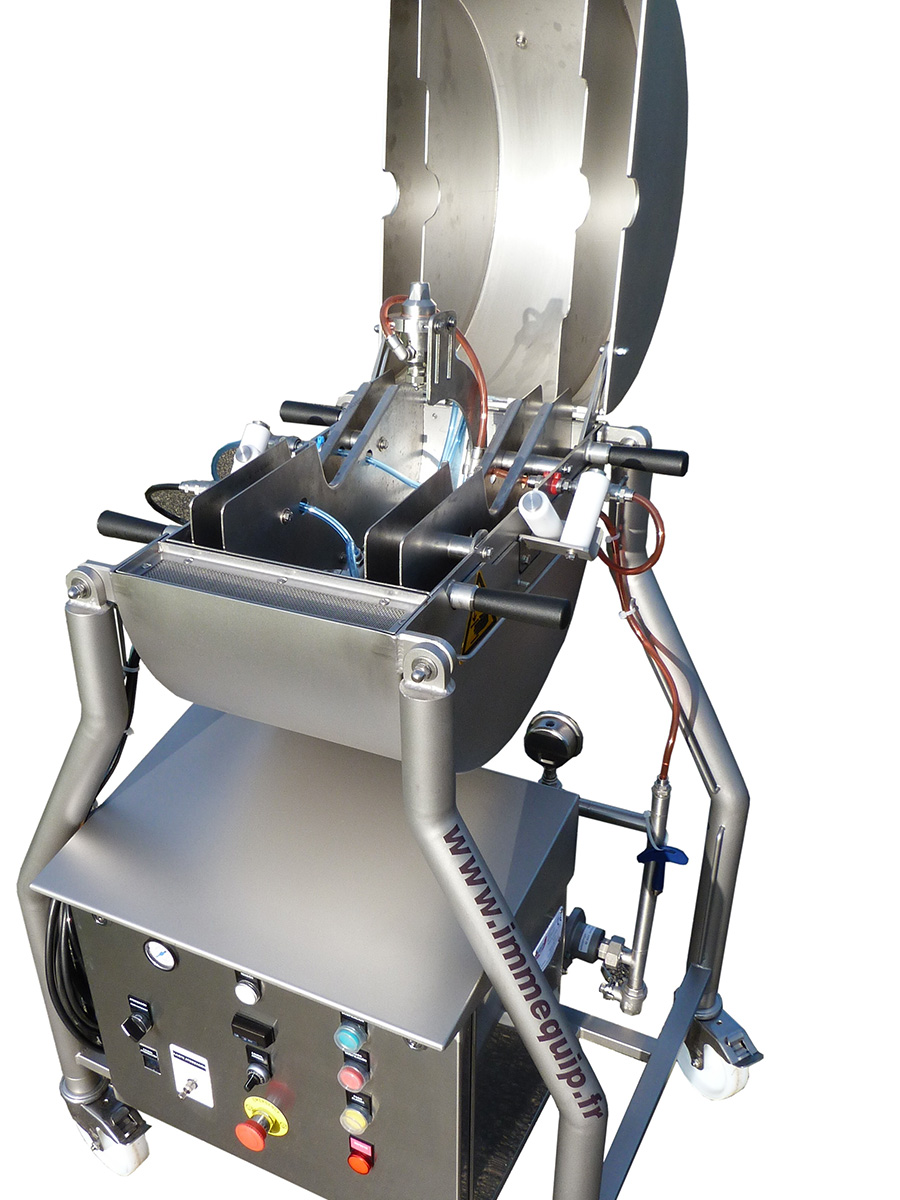

• Capacity 1 or 2 strands.

• Hygienic design, quick cleaning.

• Small standalone equipment easy to install on your extrusion lines.

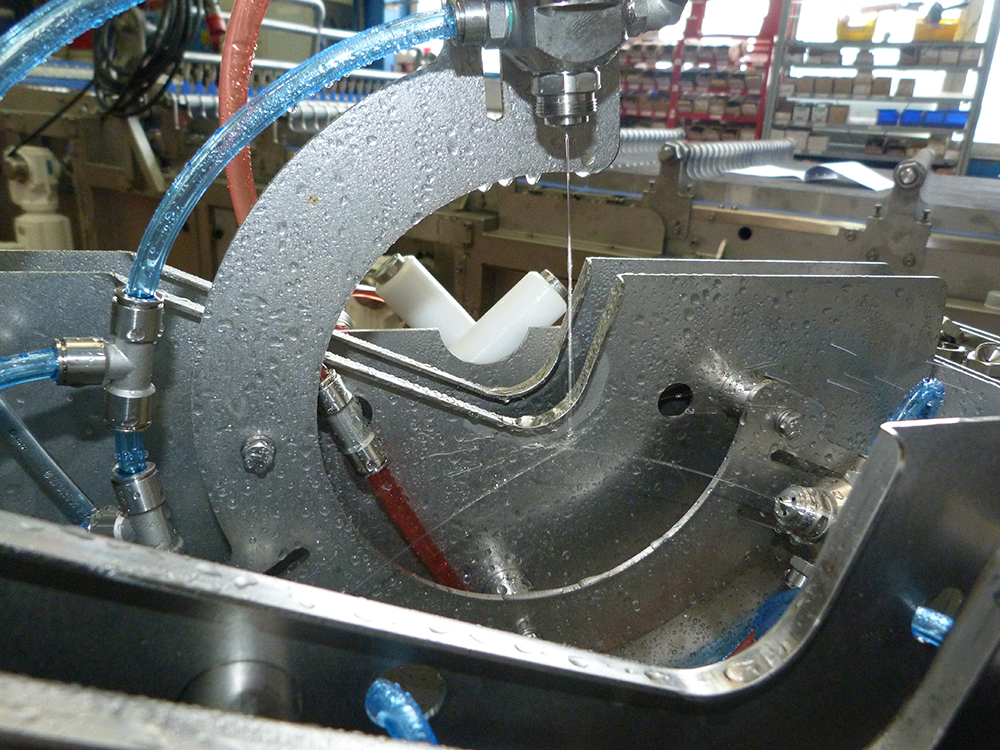

The colouring principle is based on the micro-injection of a water-based colouring solution and liquid caramel concentrate. 3 or 6 spray heads positioned at 120° spray the colourant continuously over the extrudate which thus passes through the colouring enclosure. An upper hinged casing allows the extrudate to be passed through on start-up. The latter is equipped with baffles so as to provide the best possible seal.

Speed adjustment in litre/hour allows the extrudate to be more or less coloured. Air flowrate adjustment in litre/hour allows the colourant to be more or less finely sprayed. One 600 µ filter fitted upstream of the pump provides operating safety for the spraying nozzles.